Magnet coating

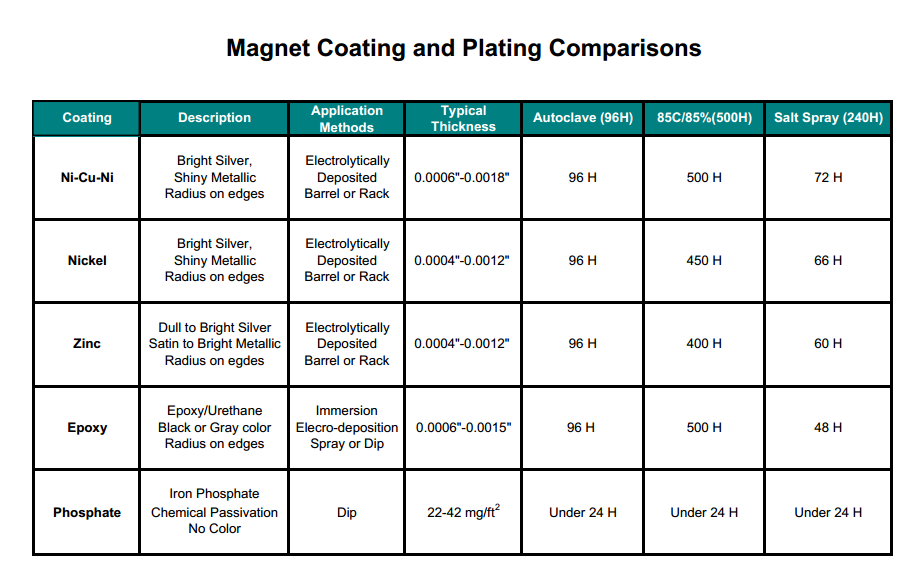

Generally Neodymium Iron Boron magnets require a protective coating / surface finish to protect them from corrosion.Coating Well-used is Nickel ,Nickel-Copper-Nickel (Ni-Cu-Ni) and Zinc.

The current range of coatings available include Nickel-Copper-Nickel (Ni-Cu-Ni),Nickel (Ni);Epoxy;Zinc (Zn);Gold (Au);Silver (Ag);Tin (Sn);Titanium (Ti);Titanium Nitride (TiN);Parylene C;Everlube;Chrome;PTFE (also known as “Teflon®”; white, black, grey, silvery);Ni-Cu-Ni plus Epoxy;Ni-Cu-Ni plus Rubber;Zn plus Rubber;Ni-Cu-Ni plus Parylene C;Ni-Cu-Ni plus PTFE;Tin (Sn) plus Parylene C;Zinc Chromate;Phosphate Passivation; and Uncoated (bare – recommend vacuum packing as well).

Other coating is also impossible,show us your unique need,we will check whether it is feasible.